Laundries and drycleaners

DataExpert s.r.o. is the certified Prefered Partner of the Swiss company DATAMARS SA for the Czech and Slovak market.

Company DATAMARS SA is a global leader in textile chips and develops and distributes this technology more than twenty years.

Chip identification of textile in laundries is one of the most advanced applications for the use of RFID technology.

Textile chip marking increases logistics efficiency of laundries

The application allows easy and very accurate tracking of textile, finding and removing of critical points in the process of washing, significant reduction of loss of laundry (up to 80%) and thus the very rapid return on investments invested in system (2-3 years). With regard to the reliability of identification the possibility of human error significantly reduces compared to manual entry and copying.

We provide development and a complete implementation of applications for identification of personal clothes and bed linen for hospitals of all categories. Hospital laundries are the biggest and the most demanding laundries on the market. There are high demands for chip resistance to the aggressive manner of washing at high temperatures, for sanitary safety and the highest possible degree of automation of the whole process of infectious textile washing without manual service.

UHF Technology

At this moment the technology of UHF chips working with a frequence coverage of 866 Mhz is the most dominant. The biggest advatages of this technology are the possibility of loading whole cages full of linen at once, easier laundry reading on a transporter and a possibility of quicker laundry stocking.

LaundryChip 401

UHF tags have the best reading performance ever and endurance in the harshest environments. Thanks to small size this tags offer no-wear feeling and unnoticable look. They´re successfully certified as OEKO-TEX Standard 100 and MR (magnetic resonance) conditional. Available in pouch (to be sewn) or in patchable version.

LaundryChip 401-PA with 2D code

Patchable UHF tags are available also in 2D-code-integrated version (QR code or Datamatrix), readable with any smartphone!

LaundryChip 401 in Roll

This "in-roll" LaundryChip configuration allow automatic insertion of the tag directly during the automatic linen manufactuirng process.

LaundryChip 403

The FT403 is the smallest LaundyChip ever and it´s perfect for those applications that can cope with shorter reading distances but where the transponder is required to be absolutely undetectable. Successfully certified OEKO-TEX Standard 100 and MR (magnetic resonance) conditional. Available in pouch (to be sewn) or in patchable version, also with 2D-code-integrated version (QR code or Datamatrix).

UHF Ironside Micro Tag

High-performance RFID transponder for tracking laundry carts, with rugged design for high durablility.

Reader R-UHF-SR420/SR220

UHF Stacionary reader available with 2 or 4 ports. Also available with Cloudburst, a software layer developed specially for laundry needs.

Reader R-DT-UHF-CW-RS232-101

All-in-one stacionary reader with integrated antenna perfect for light industrial usage.

S-UHF-PORTAL-201

The Portal-201 is a heavy duty reading portal designed to read trolleys on the soil side of the laundry, typically at the truck inloading area.

S-UHF-PORTAL-PLUS

The Portal-PLUS has been designed to read carts on the clean side of the laundry and it can be used in any area where bulk reading is needed without slowing down the textile flow.

S-UHF-TUNNEL-201

The UHF Open TUNNEL-201, powered by artificial intelligence (RFAID), has been designed to be mounted on any existing laundry conveyor belt and is the perfect reading system to read clean stacks of textiles.

S-UHF-LITECAB-101

Manually operated single door cabinet provides very reliable reading of the carts. Litecab is easy and quick to install and is typically used in dispatching area of the laundry.

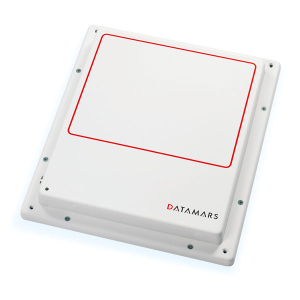

Anténa A-UHF-CON

Conveyor antenna has been designed for reading on conveyor belts and can be used in any area where larger distance reading is needed.

Anténa A-UHF-TT AO-101

TableTop antenna is used for combine reading LF/HF-UHF where is reading of laundry stacks or individual pieces of laundry needed.

Anténa A-UHF-LNG-101

UHF hanging conveyor antenna allows to precisely identify UHF tagged textiles thanks to an homogenous reading area.

RFID USB microreader (UHF)

This small USB reader is used where is reading of individual pieces of laundry needed, typically during the laundry takein process or in repair department.

HF Technology

An older technology that is today more on a fallback. Despite this it is still getting implemented in new installations, that need to read laundry that is moist or not completelly dry (hospitals, retirement homes etc.). In those circumstances the HF technology is more reliable than the UHF. All HF technology antennas and transponders work on a 13,56 Mhz frequency. The antennas enable a scanning system – Multiread, which lets the user scan multiple identifiers at once.

T-BT1315 HTX „ORION“

This transponder (chip + antenna in protective shell) has been designed for laundry that gets washed and cleaned in extereme conditions usually in hospital laundries (temperature up to 220°C, pressure up to 50bar).

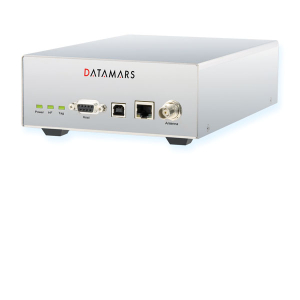

Reader R-IN1300 MID

Stacionary reader (2W, serial & USB port).

Reader R-IN300 MC

Stacionary reader MC with 9 antenna connectors.

A-ST1360 TUN

Samostatně stojící anténa určená k hromadné 3D identifikaci, především špinavého nebo infekčního prádla umístěného ve vacích.

infekčního prádla umístěného ve vacích.

A-ST1300 CHUTE

Antenna designed mainly for 3D personnel laundry identification.

A-ST1330 TT

TableTop antenna designed for 2D laundry identification. This antenna is mainly used for clean laundry reading and is placed on the table or in it´s construction.

The main benefits of implementation of hospital textile identification

Unique textile identification

• Evidence and optimizing the laundry movement and associated costs

Reduction of textile loss

• up to 80% (c. 60% in the first year of system launching) and precise determination of location where the laundry is mostly disappearing

Minimizing unused reserves of textiles on departments and therefore the necessary storage space, reducing the risk of thefts

Flexibility of laundry delivery to the customer

Evidence of damage depending on the laundry customer, customer anonymity revocation, possible recovery.

• Increase of productivity by reducing disputes between the customer and the laundry

• Linen quality control according to suppliers and supplies, managing relationships with suppliers.

• Easier to evaluate the cost of washing and repairing of textiles

Quick return of investment (2-3 years)

• Simple servicing, the possibility of immediate outputs from the system